知识中心

设计定制传感器

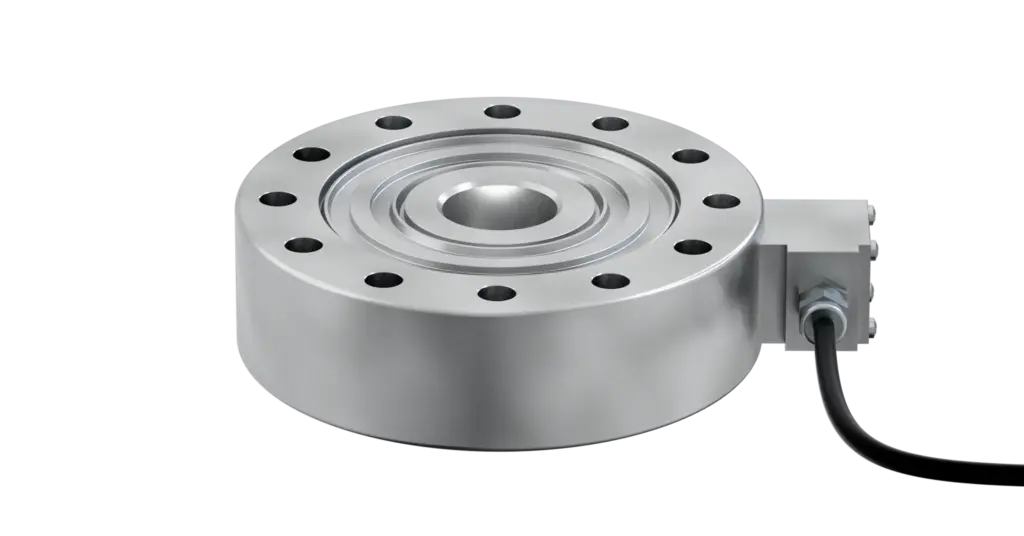

本页内容更新于2024年6月11日ANYLOAD custom load cells are developed to meet the specific needs of various industries, ensuring precision and reliability in specialized applications. This section covers the design, functionality, and benefits of custom load cells, offering valuable information for professionals seeking advanced weighing solutions.

Understanding what is a custom load cell, the common rationales driving customization, and the standard process for developing and manufacturing custom load cells is helpful to engineers, QA managers, researchers, and purchasers in finding a weighing or force measurement solution that best suites their needs.

1. What is a Custom Load Cell?

A custom load cell is simply a load cell that is specially configured during the design and manufacturing process according to the requirement of the client. It ranges from basic requests such as a specific cable length or a variation in output to completely new load cell designs intended for highly specialized applications. ANYLOAD defines custom requests in the following three ways:

MODIFICATION

Minor

Change Requirements

(Modifications of a standard load cell)

- Cable length/type/connector

- Output

- Thread size

- Embedded surge protection

- Overload or sensitivity adjustment

- Material/coating change

CUSTOMIZATION

Common

Change Requirements

- Unique dimensions requiring retooling

- Embedded A/D converter

- Digital output

- Multi-bridge redundancy

- High temperature resistance

- Configuration for in-motion or process weighing application

INNOVATION

Major

Change Requirements

- Miniaturization

- Multi-axial sensing

- Integrated testing and validation

- Very high precision and/or durability

- Extreme environmental resistance (vacuum, underwater, aerospace applications, etc.)

At ANYLOAD, only major design projects involving significant research and development efforts may require a non-recurring engineering fee to proceed beyond initial consultation and scoping.

2. Reasons to Develop a Customized Load Cell

Why Consider Customized Load Cells?

Strain gauges are precise sensors used to measure mechanical deformation – specifically, the strain of an object. When external forces are applied to an object, stress and strain are the result. Strain is the ratio of the deformation to the original length, and measuring this strain can tell us a lot about the performance and structural integrity of the material or object being tested. When a strain gauge is bonded to a strationary object, it can thus measure the stress or strain it experiences and convert that into an electrical output in the form of changes to resistance.

Physically, a strain gauge consists of a thin, metallic foil pattern – the “gauge” – placed onto a flexible backing material, known as the carrier. The foil is usually arranged in a zig-zag pattern to maximize its length within a small area, which increases its sensitivity to strain. When bonded to the surface of the material under test, the gauge deforms along with the material.

a) When Standard Solutions Fall Short

There are situations where standard load cells, even with modifications, cannot meet the rigorous demands of a specific application. In such cases, customized load cells become essential. When your application has unique or stringent requirements that standard load cells cannot fulfil, a custom-designed load cell ensures satisfactory performance and reliability.

b) The Value of Custom Load Cells

Custom load cells can offer significant benefits to many organizations, helping to achieve a variety of goals and priorities:

OEMS

Gain a competitive edge by integrating load cells that perfectly match your product specifications, enhancing performance and customer loyalty.

- Optimized load cell performance

- Simplify integration / minimize disruption

- Propel efficiency and innovation

Engineers

Simplify complex or inefficient designs with weighing and force measurement solutions tailored to your exact specifications, improving overall system efficiency and reliability.

Purchasers

Invest in solutions that offer long-term value by reducing downtime and maintenance costs associated with poorly fitting standard components.

Quality Assurance (QA)

Simplify complex or inefficient designs with weighing and force measurement solutions tailored to your exact specifications, improving overall system efficiency and reliability.

Researchers

Drive innovation with load cells designed to meet your unique research requirements, allowing for accurate data collection and analysis.

c) Strategic Advantages of Custom Load Cells

Opting for custom load cells provides strategic advantages that go beyond performance and integration:

Enhanced Brand Loyalty: Customized load cells tailored to your specific needs can lead to higher customer satisfaction and loyalty, as they offer superior compatibility and reliability in your products.

Intellectual Property Protection: Custom load cells can be part of your intellectual property strategy, protecting your unique designs and innovations from being easily copied by competitors.

Control Over Parts and Service: Using custom load cells allows OEMs to maintain better control over the parts and services related to their products.

Advantages

- Fully adapted for applicational requirement

- Simplify complex or inefficient designs

- System optimization

- Increased operating efficiency

- Stronger IP protection & brand loyalty

- Competitive advantage

Challenges to Consider

- No immediate product availability

- May affect cross-compatibility with standard products

- May incur retooling and development costs

- May require re-certification with certain relevant compliance bodies (if applicable)

3. Developing a Customized Load Cell

The custom load cell development process begins with a detailed consultation. During this phase, we focus on requirements scoping and gathering additional information to fully understand your specific needs.

Our team works closely with our clients to:

- Evaluate if an existing standard product might meet specified requirements

- Assess business and technical requirements

- Confirm load cell specifications, performance criteria

- Identify any unique features required for the application

Our Custom Load Cell Order Form outlines in meticulous detail the large variety of performance, safety, integrational, durability, and other requirements that may be specified by the client or our design team.

The design phase is iterative, incorporating feedback from your technical team to refine the load cell design. Our experienced engineers collaborate with your team to create detailed design plans, ensuring all technical and functional requirements are met. This collaborative approach ensures the design aligns perfectly with your expectations and application needs.

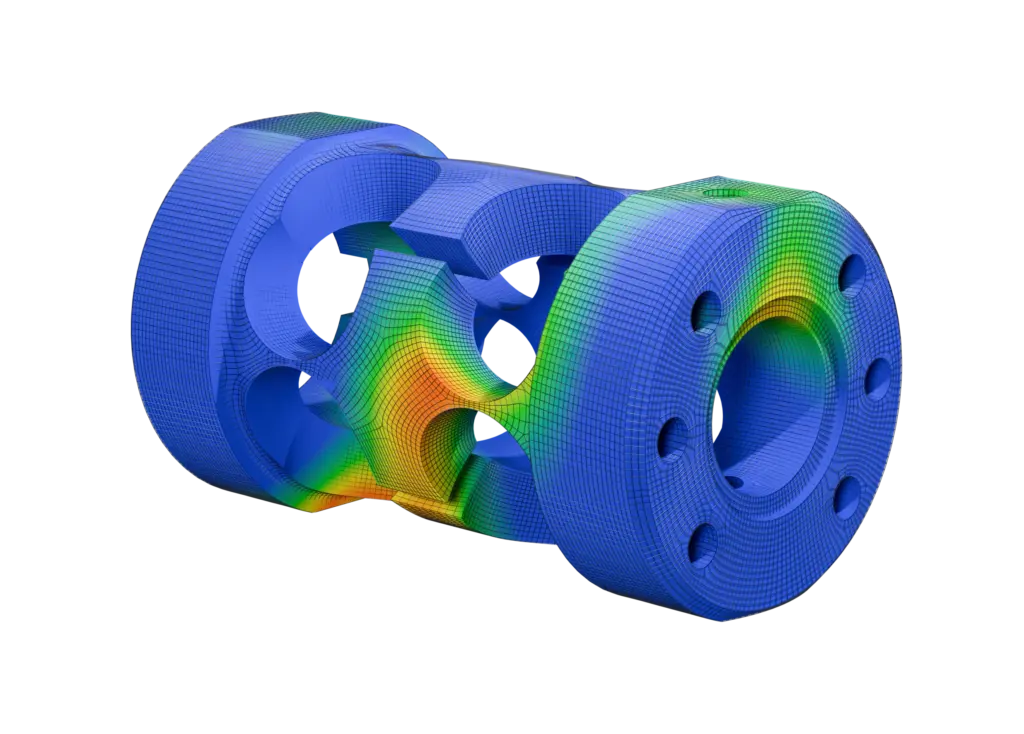

We utilize finite element analysis (FEA) to simulate the load cell’s performance under various conditions. This advanced simulation technique allows us to predict how the load cell will behave under different loads and stresses, identifying potential issues and making further optimizations.

By using FEA, we can optimize the design for strength, durability, and accuracy, ensuring the final product meets or exceeds your performance and safety requirements.

Depending on the complexity and specific requirements of your project, prototyping and testing are conducted to validate the design. We provide samples for evaluation, allowing you to test the load cells in real-world conditions. This step ensures that the custom load cells meet all performance standards and application requirements before moving to full-scale production.

Once the prototypes are approved, we move to the production phase. Manufacturing instructions, procedures, and techniques must be developed to manufacture the new load cells. Load cell engineers must coordinate with assembly line technicians to ensure that designs are realistic to produce and can be made reliably and efficiently. CNC equipment must be configured, other machinery retooled, and further automation may be applicable depending on the quantities required.

Our state-of-the-art manufacturing facilities ensure high-quality production of your custom load cells. We maintain strict quality control measures throughout the production process to ensure each load cell meets or exceeds all specified standards and performance criteria.

If you want to learn more about how load cells are manufactured, click here.

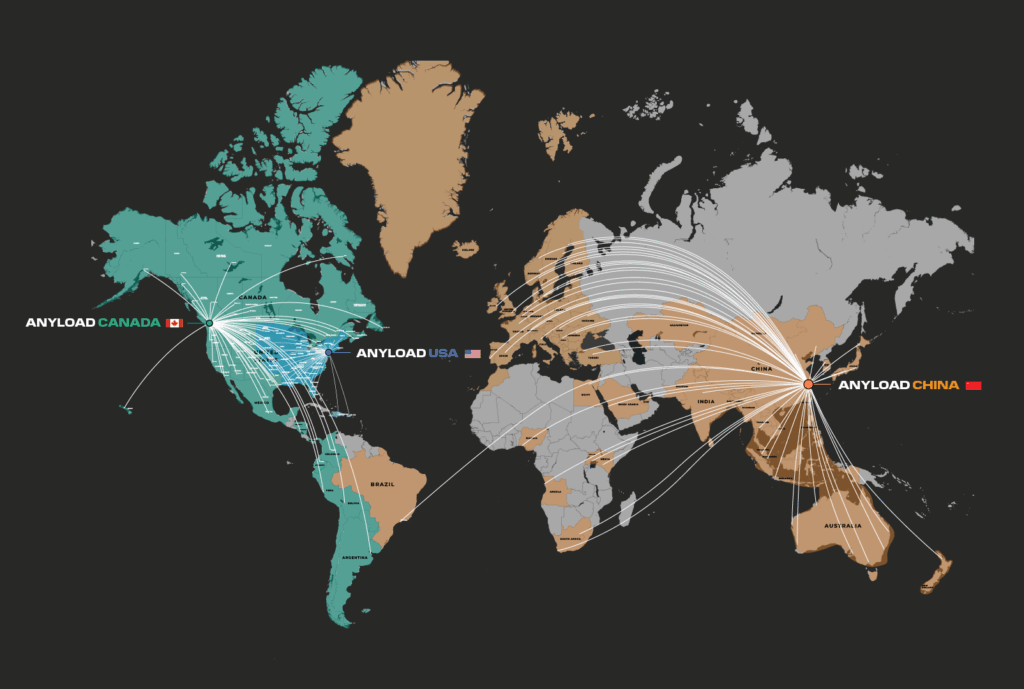

After production, we help to handle the fulfilment of your custom load cells, ensuring timely delivery to your location. Our support doesn’t simply end with delivery.

Beyond our product, we offer by default:

- We offer ongoing technical support and assistance to ensure seamless integration

- Our global network of dealers and distributors are able to provide on-site services

- ANYLOAD distribution hubs can serve as staging and buffer inventory locations for regular ordering

- ANYLOAD products are covered by our manufacturer’s warranty, with options for extended warranties for custom projects

4. Choosing the Right Partner for Custom Load Cells

Expertise

It is essential to choose one with extensive expertise and experience in designing and manufacturing custom load cells. Many suppliers are primarily focused on manufacturing standard products and may lack the experience or setup needed to develop tailored solutions based on specific applicational requirements.

Collaborative Approach

A partner that adopts a collaborative approach, working closely with your team throughout the development process, will help ensure the final product meets your exact specifications. We pride ourselves on our iterative design process, which involves continuous feedback and cooperation with your engineering team to ensure the load cells are perfectly suited to your application.

Quality Assurance

Quality is paramount when it comes to custom load cells. This is especially critical in custom projects as new materials, configurations, and procedures are much likelier to cause unforeseen challenges. Experienced engineering, production line technicians, purchasers, and QA personnel all working effectively is essential in any successful custom design project. Check out Anyload’s quality assurance here.

Flexibility

Designing and producing custom load cells necessitates flexibility in accommodating technical and business requirements. This can be a challenge for companies that do not have access to experienced application engineers during development, specialized testing equipment during prototyping, and the scalability to increase production. Some suppliers may have difficulties scaling up production to meet eventual demand, while others require high starting quantities immediately, or impose exorbitant development costs.

Why ANYLOAD? Choosing ANYLOAD as your partner for custom load cells ensures you benefit from:

-

- Direct Manufacturer Advantage: As your manufacturer, designer, and distributor, we provide better service, more reliable products, and quicker turnaround times.

- Experienced Solutions Provider: We have a proven track record in designing and manufacturing load cells that meet specific application requirements, enhancing performance and reliability.

- Seamless Integration: Our collaborative approach and iterative design process ensure the final product integrates seamlessly with your systemss

- Flexible and Scalable Solutions: We offer cost-effective solutions that can scale from prototype development, single-unit orders, to full-scale production, ensuring you receive the support you need at every stage of your business.By partnering with ANYLOAD, you gain access to industry-leading expertise and comprehensive support, ensuring your custom load cell development process is smooth, efficient, and tailoed to your precise needs. Contact us today to learn more about how we can help you with your custom load cell requirements.